In 2018, I worked with a Dutch start-up called Carice to design a new version of their electric car with an aluminium body. The work involved understanding the available manufacturing processes and designing the car and its parts accordingly to suit these processes.

A CAD model of the entire car was created and then split into different panels, parts and assemblies.

Manufacturing

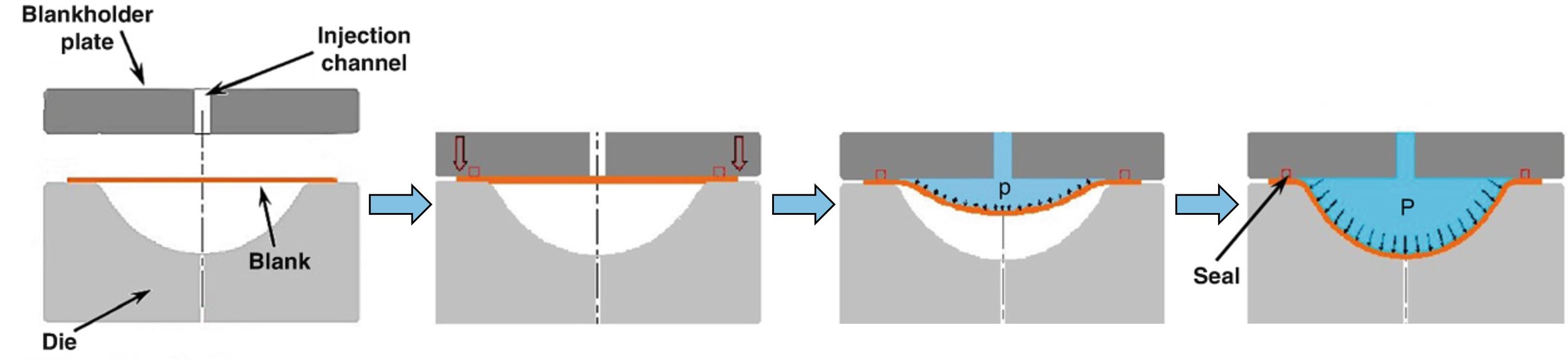

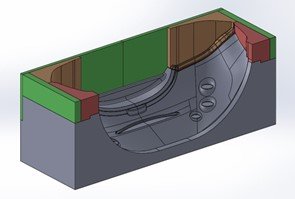

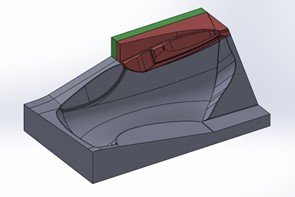

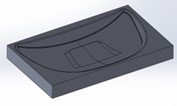

As the selected method of manufacturing for the aluminium body panels was hydroforming, individual panel moulds were designed accordingly.

Hydroforming process

Front bumper mould

Rear bumper mould

Front fender mould

Rear fender mould

Trunk mould

Trunk inner plate mould

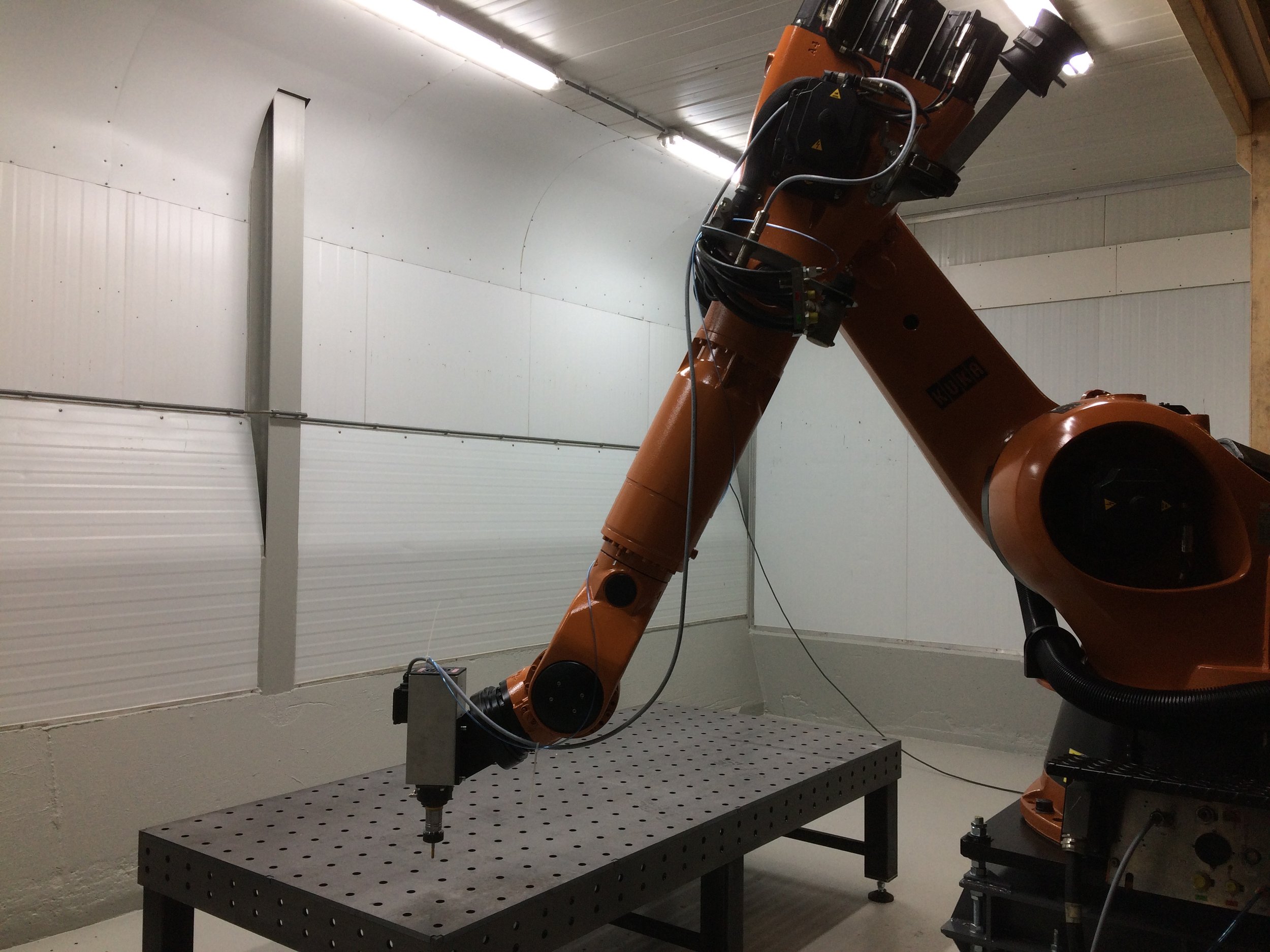

These models were then machined out of high density polyurethane foam using a Kuka milling robot.

Component design

Besides the body, some other parts were integral to the convertible design of the car.

A special forming mould was created in sheet metal to mould the curved windscreen

A 2.5D rig of the convertible mechanism was created to verify the open/close and latching mechanism

As a part of detailing the car, other small plastic and metal components were also designed in line with the design language of the car.

Carice logo

Interior dashboard